PT'ZM supplies high-strength sprockets for Komatsu excavators, manufactured through precision casting or forging with alloy steel. Each sprocket undergoes tempering and deep quenching processes, providing excellent impact resistance and long-term wear performance. These undercarriage components are suitable for demanding operations such as heavy construction, quarrying, mining, demolition, and forestry.

Compatible Komatsu Models

- PC3000 / PC2000 / PC1250: Designed for 200-300 tons mining excavators

- PC800 / PC400 / PC360 / PC300: Suitable for 30-80 tons earthmoving and quarrying equipment

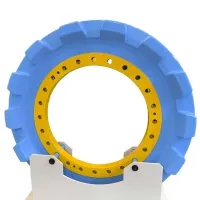

Excavator Sprocket

How can you extend the service life of your undercarriage system?

How can you extend the service life of your undercarriage system?

- Adjust the track tension regularly to ensure proper alignment and reduce stress.

- Keep the tracks clean. Accumulated dirt, mud, and debris increase wear, reduce efficiency, and raise fuel consumption. Use a pressure hose to clean tracks daily, ideally before or after each shift.

- Limit reverse operation. Forward movement causes less wear than reversing, which also increases fuel usage.

What are the types of sprockets used in construction equipment?

What are the types of sprockets used in construction equipment?

There are many sprocket types, but commonly used ones include: standard sprockets, double-row sprockets, industrial sprockets, drive sprockets, triple-row sprockets, hub sprockets, single-row sprockets, single/double pitch sprockets, drum sprockets, steel split sprockets, idlers, bushing sprockets, multi-strand sprockets, quick-disconnect sprockets, and taper-lock sprockets.

What role does the sprocket play in the undercarriage system?

What role does the sprocket play in the undercarriage system?

The sprocket transfers engine power to the track chain, allowing the machine to move forward or backward. It engages directly with the track links to maintain smooth and efficient operation, even on uneven terrain. A properly functioning sprocket also helps preserve track tension and reduces wear on other undercarriage parts.

How often should you inspect your undercarriage components?

How often should you inspect your undercarriage components?

For frequently used excavators, a daily inspection is recommended. Look for wear indicators such as cracking, loose components, or uneven tension. Regular checks help detect issues early and prevent costly repairs.

Can undercarriage parts be replaced individually?

Can undercarriage parts be replaced individually?

Yes, individual components like tracks, rollers, or sprockets can be replaced separately. However, replacing multiple parts together may improve alignment and reduce uneven wear. Consult our technical team to find the most effective replacement plan for your equipment.

How should you maintain the track chain to extend its service life?

How should you maintain the track chain to extend its service life?

Regular lubrication minimizes friction and wear. Clean the track chain after each use to remove dirt and debris. Monitor tension and replace worn pins or bushings promptly to avoid further damage to the assembly.