With over 30 years of experience in producing heavy equipment undercarriage components, PT'ZM applies strict OEM 1:1 dimensional control throughout the manufacturing process to ensure full compatibility and reliable performance. All components are produced using high-strength materials, including forged 40MnB2 boron steel and 42CrMo alloy steel, delivering excellent wear resistance and durability. Each part undergoes precision heat treatment to achieve the required surface hardness and structural integrity, allowing the components to perform reliably under demanding mining operations and high-impact construction environments while meeting the original material performance standards.

Forging

Metal billets are plastically deformed under high pressure using forging equipment to produce parts with superior mechanical strength, precise shape, and reliable dimensional stability.

Precision Casting

Molten metal is poured into molds through controlled casting processes, including both sand casting and specialized casting methods, to produce complex parts with consistent quality and performance.

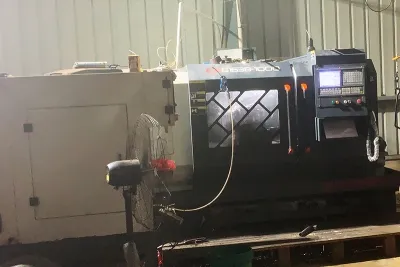

Precision Machining

Components are machined with high accuracy based on detailed technical drawings, ensuring strict adherence to OEM specifications.

Surface Treatment

Components undergo precision heat treatment processes to achieve optimal hardness and wear resistance for heavy-duty applications. Core processes include annealing, normalizing, quenching, tempering, hardening & tempering, aging treatment, carburizing, and nitriding to enhance material properties and extend component service life.